Heat Exchanger

Heat Exchanger

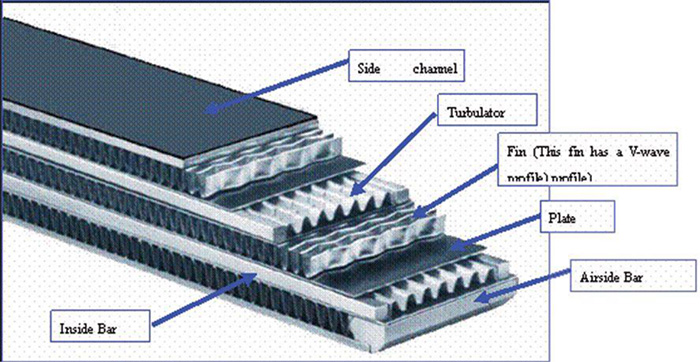

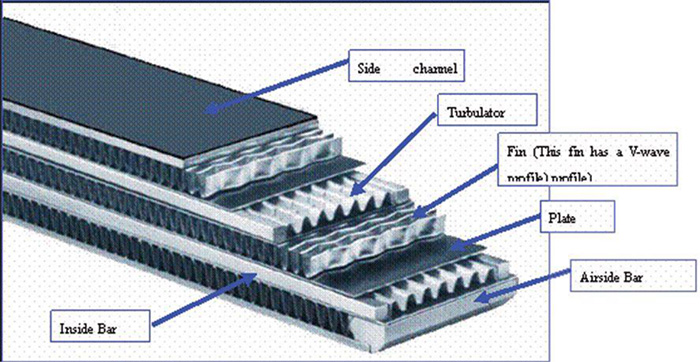

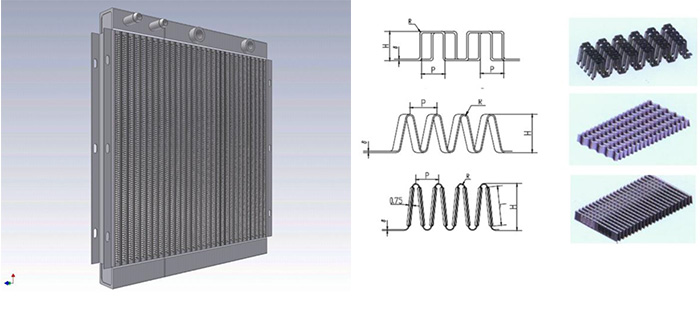

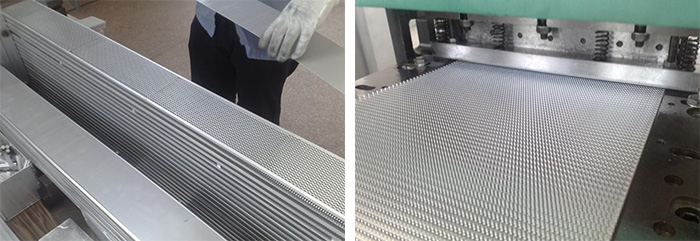

Structure Core

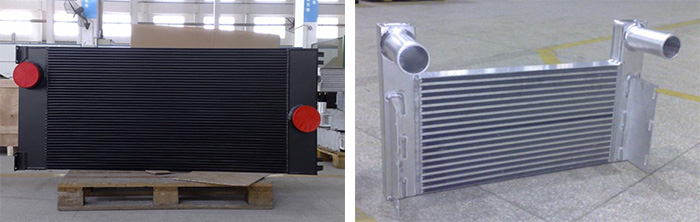

Aluminum bar & plate core structure (with different turbulators)

- Better heat transfer performance: Aluminum heat transfer better than stainless steel.

- Lighter: Aluminum only 30% weight comparing to copper and brass.

- Stronger: Bar-plate structure, turbulators inside, aluminum brazing.

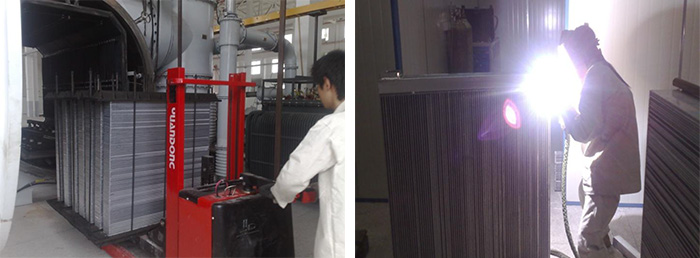

- Clean: All components should be clean when brazing, no flux needed.

- Flexible: Products dimension range is very wild. From small cooler to very huge heat exchanger. Several cooler core can be welded together to enlarge the size.

- Cheaper: No special mould needed for low volume but many mode.

Our Products:

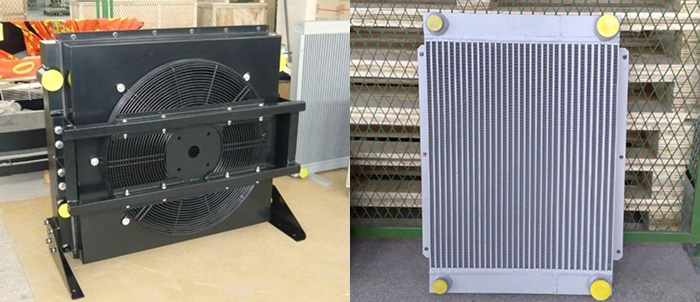

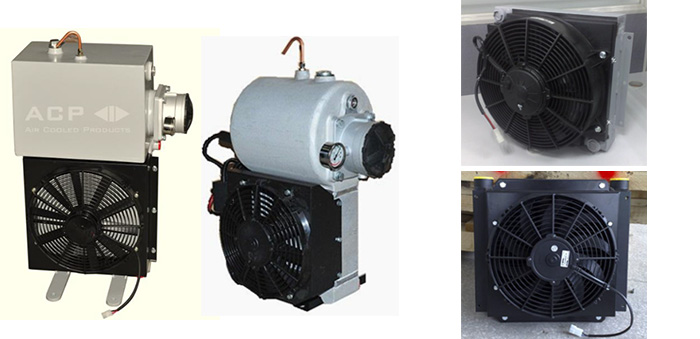

Air/Oil Combi-cooler for air compressors

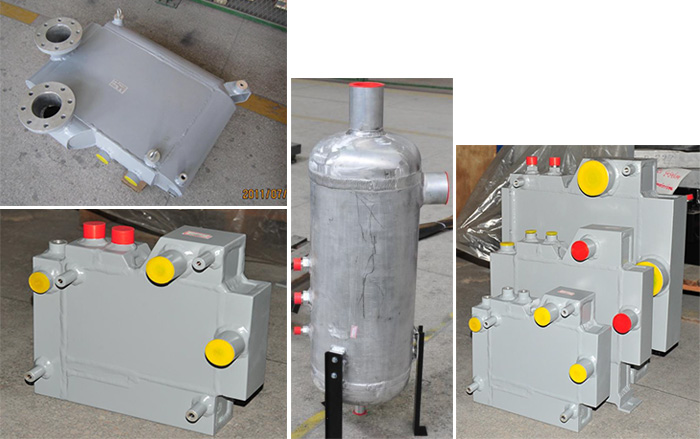

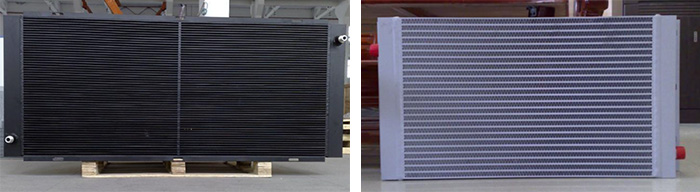

Pre-cooled heat exchanger for refrigerated air dryer

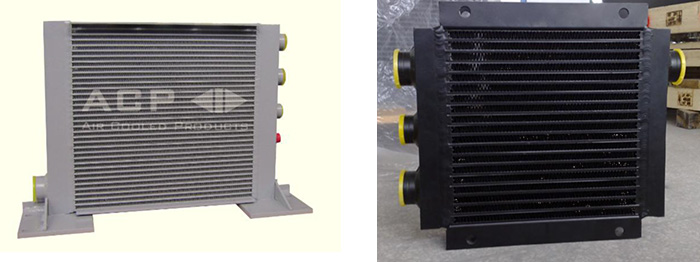

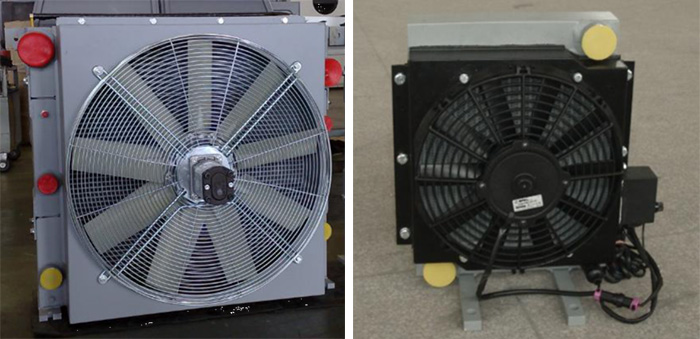

Hydraulic Oil Coolers

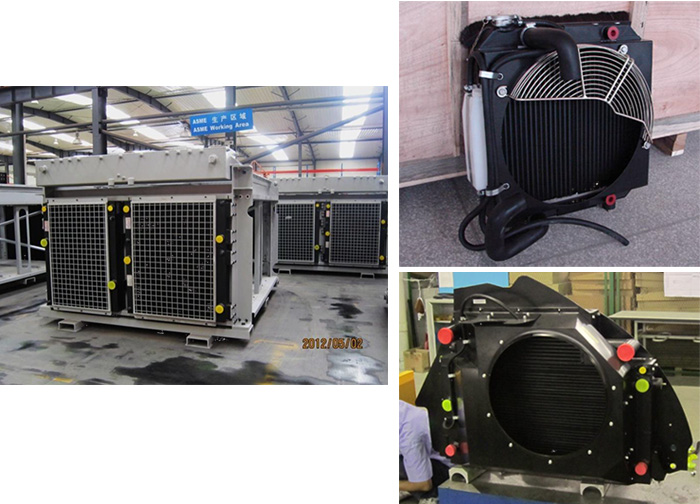

CAC/Radiator/Hydraulic oil combi-coolers for construction machinery

Customized Cooling Package

Coolers for wind power generators

Charge Air Cooler

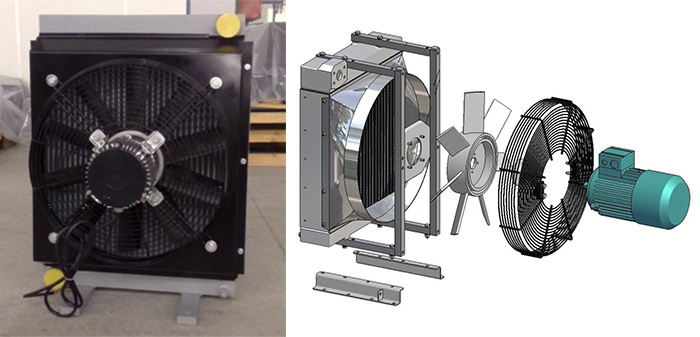

Cooking package including fan shroud, fan, fan motor( DC/AC/Hydraulic ), thermostat etc.

Cooking package including fan shroud, fan, fan motor.

Cooling solution including fan shroud, fan, fan motor.

Main applications:

- Hydraulic and mobile systems,

- Mobile and stationary lubrication systems

- Charge Air cooler, Engine cooler

ACP offers full-service all around the topic (aluminium) cooler elements

That stands for:- customised cooler production according to your thermal data and your drawing...

- customised cooler production according to your thermal data / assembly data and our design...

- customised complete solutions (cooler incl. fan, shroud, protective grid, fan motor etc.)

- all services directly from one hand

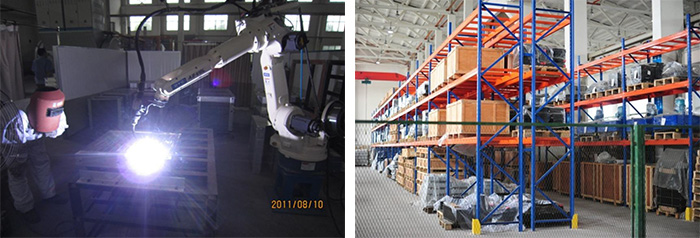

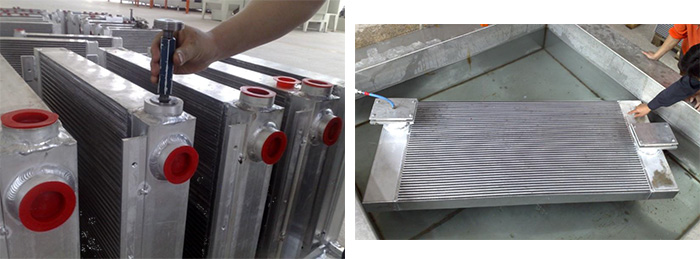

Quality Control: Components inspection

Assembly Inspection:

- 100% Leakage test and pressure test.

- Each product given serial number.

- Special products Helium leakage test.

- Analysis and improvement continuous.

- Max burst pressure: 185bar.

Top Class Quality:

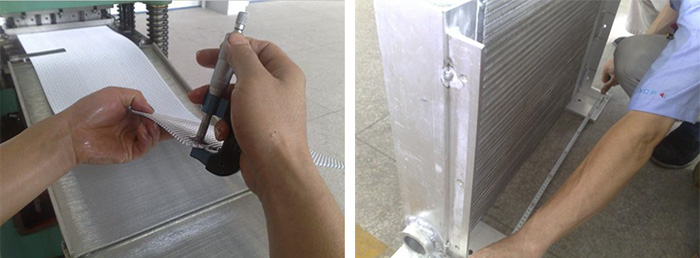

- Raw material components inspected strictly

- Each process be controlled strictly

- Each piece of cooler be leakage tested and pressure tested before delivery

- Advanced manufacture technical

- Top Class brazing core, max 185bar burst pressure, >85% first pass rate.

- Better Service

- Easy to Communicate

- Rapid response to customer

- Stronger technical support

- Short delivery time

- Service partner in Europe

Competitive Price:

- Quality of top class

- Price of low costs

Our Certificates: